Contact Us

Contact Us

Mid North Coast Aluminium Welding

Whether you're building something new or extending the life of an existing structure, the quality of your aluminium welding can make or break the project. At Oz-Craft in Taree, we specialise in delivering expertly welded aluminium components designed to withstand the harsh conditions of the Mid North Coast—whether it's the salty coastal air, high moisture levels, or constant sun exposure.

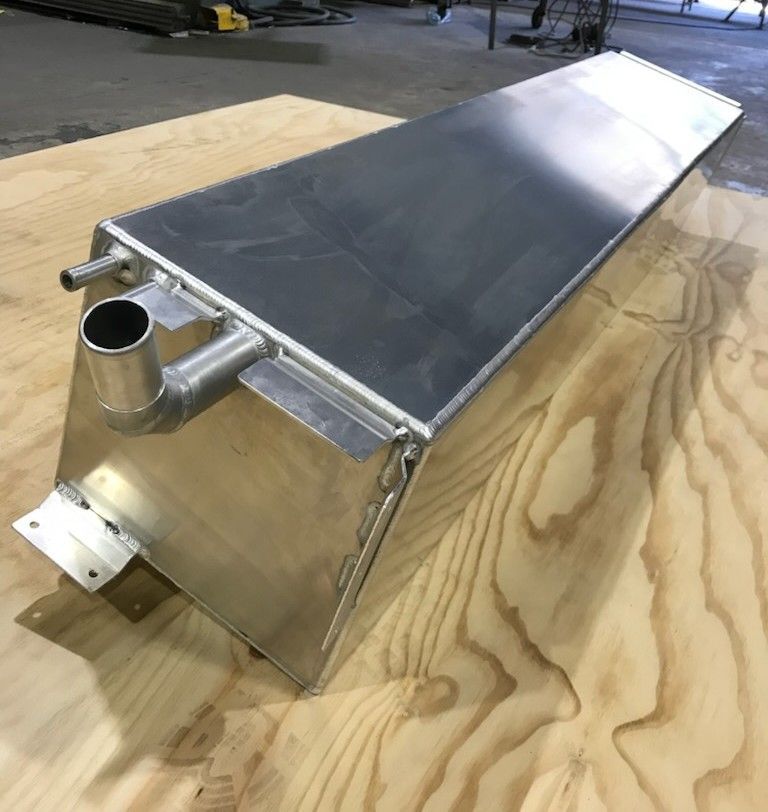

Our clients rely on us for clean, precise welds that not only meet structural requirements but also enhance the overall finish of the project. From intricate decorative pieces and modern gates to heavy-duty marine fixtures and commercial fittings, our welding work is always driven by a focus on strength, accuracy, and appearance. We use the latest welding techniques to ensure consistent results, even on complex jobs that require custom fabrication or specialised alloys.

If you're in Taree or across the Mid North Coast and want your aluminium welded right the first time, contact Oz-Craft on 02 6554 6992 for expert advice and dependable results.

Obtain a Quote

Welded with Purpose

Aluminium might be one of the most versatile metals on the market, but it’s also one of the most difficult to weld properly. Its lightweight, excellent corrosion resistance, and non-magnetic properties make it ideal for many industries—construction, marine, transport, and architectural design included.

But without the right tools and techniques, welding aluminium can result in weak joins, cracked finishes, and premature failure. That’s why tradespeople, builders, and property owners across the Mid North Coast turn to professionals like Oz-Craft when quality matters.

Our team understands how to work with different grades and thicknesses of aluminium, ensuring every weld delivers the required strength and durability for long-term use. We approach each project with careful planning and precision, accounting for the metal’s conductivity, melting point, and application environment.

The result? Welds that are not only structurally sound but also clean and professional in appearance—ideal for both visible installations and load-bearing parts. A high-quality weld today can prevent costly repairs tomorrow.